What is 3D Printing?

3D Printing is a manufacturing process which builds real, solid objects from digital models found in computer files. 3D Printing has been around for decades in various forms, but wide-spread public accessibility has skyrocketed in recent years as prices have dropped dramatically, and the number of available technologies has blossomed.The digital world is abuzz with news and commentary on 3D printing even as much of the world has never heard of it. There are hundreds if not thousands of sites on the Internet promoting the services and products of 3D printing and chronicling highly technical developments in the industry, but is the public at large being left out, buried in technobabble? As artists and designers are one of the fastest growing groups to benefit from 3D printing I feel it is more important than ever not to leave anyone out of this technological revolution. Fear no more. Here is a basic explanation for artists and lay persons.

|

| A Commercial 3D Printer |

Why 3D Printing?

So, what’s so special about a machine that can 3D print an object from a drawing I made on my computer? There are several major benefits I’ll explain here:It’s Automatic

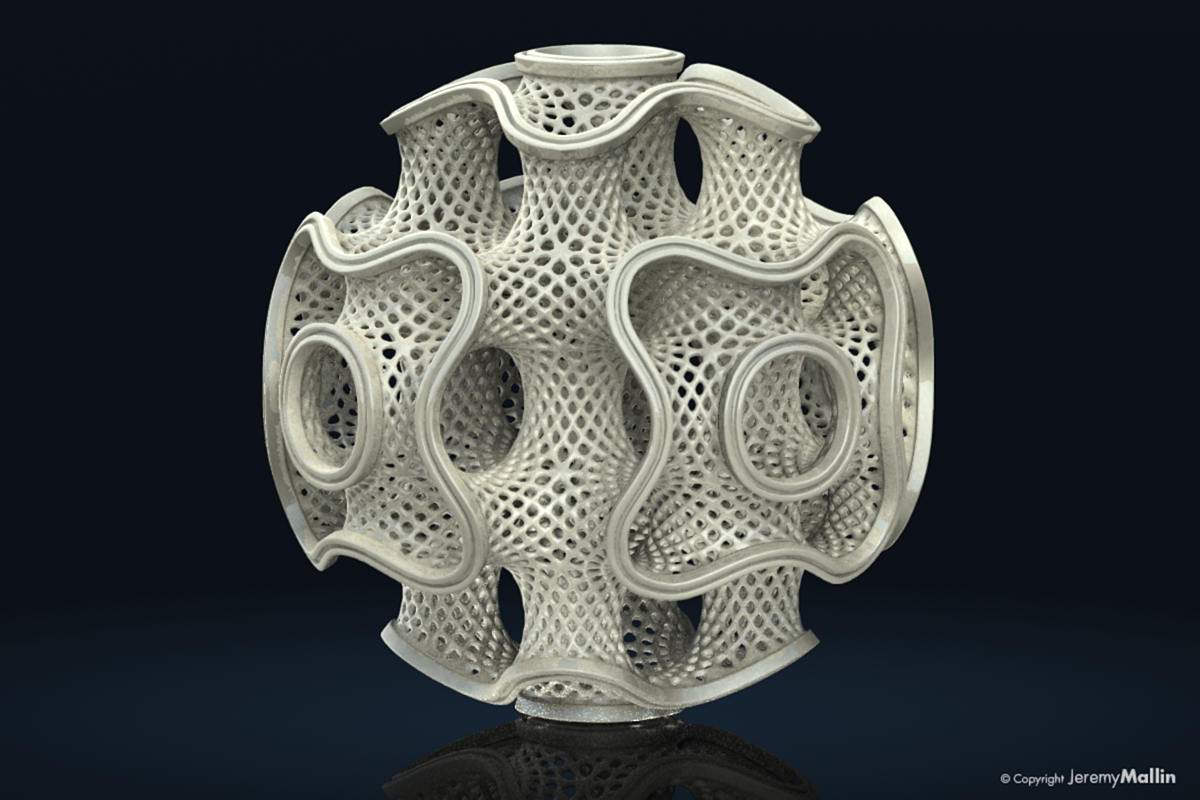

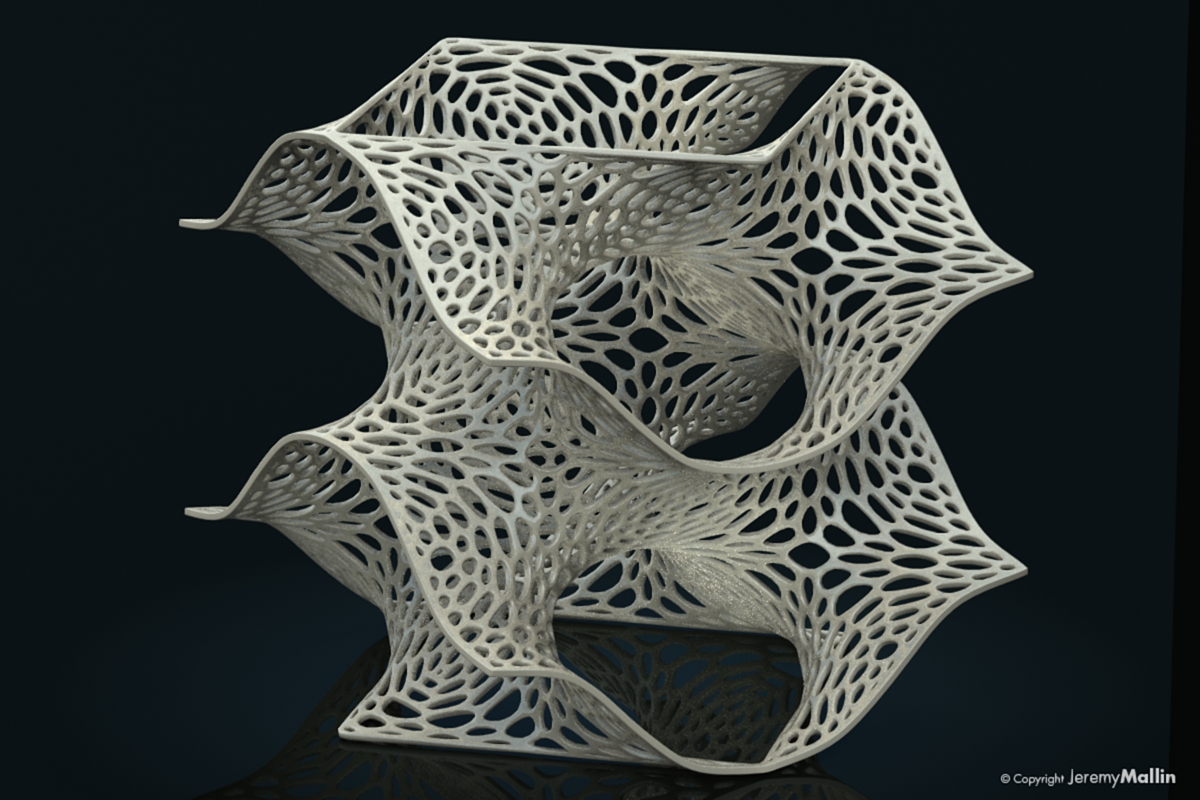

Since the 3D printer automatically generates the object from a designer’s drawing, minimal engineering or manufacturing knowledge is necessary to get great, professional results. There isn’t the same need to know or calculate how a 3D printer will create an object or to systematically program a step-by-step procedure for the machine to follow as there is with other prototyping and manufacturing processes. 3D printing is almost as simple as sending your family photos to your desktop printer without any need to know how to develop photographic film.The Impossible Is Possible

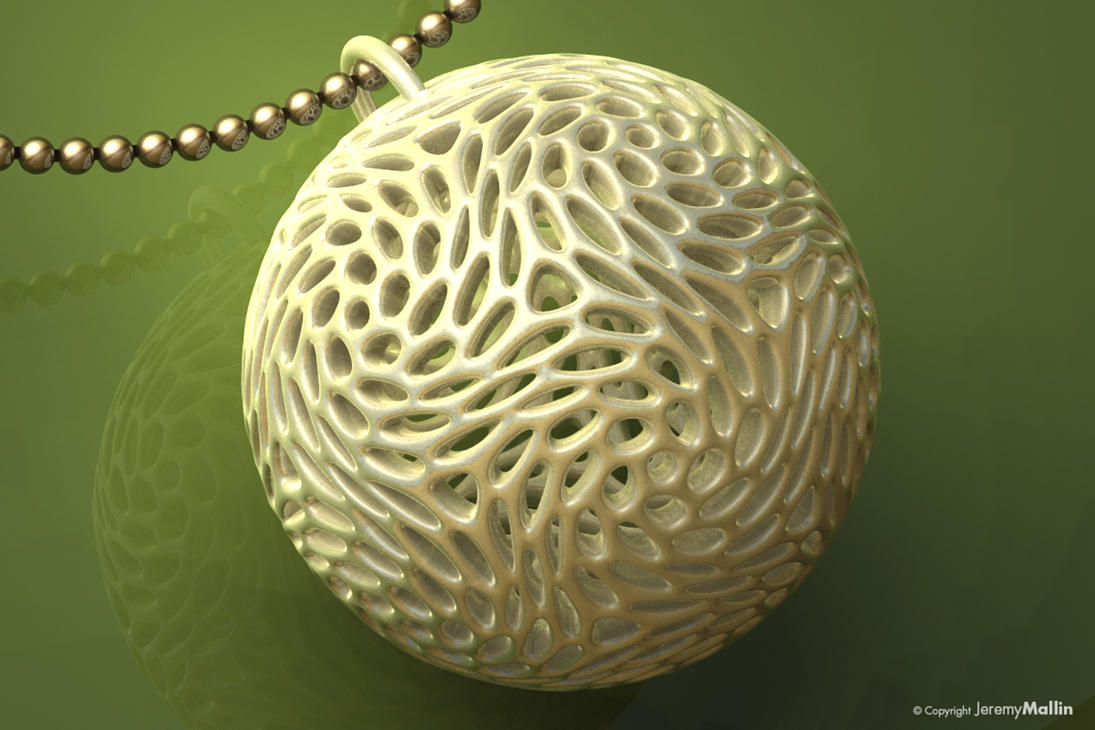

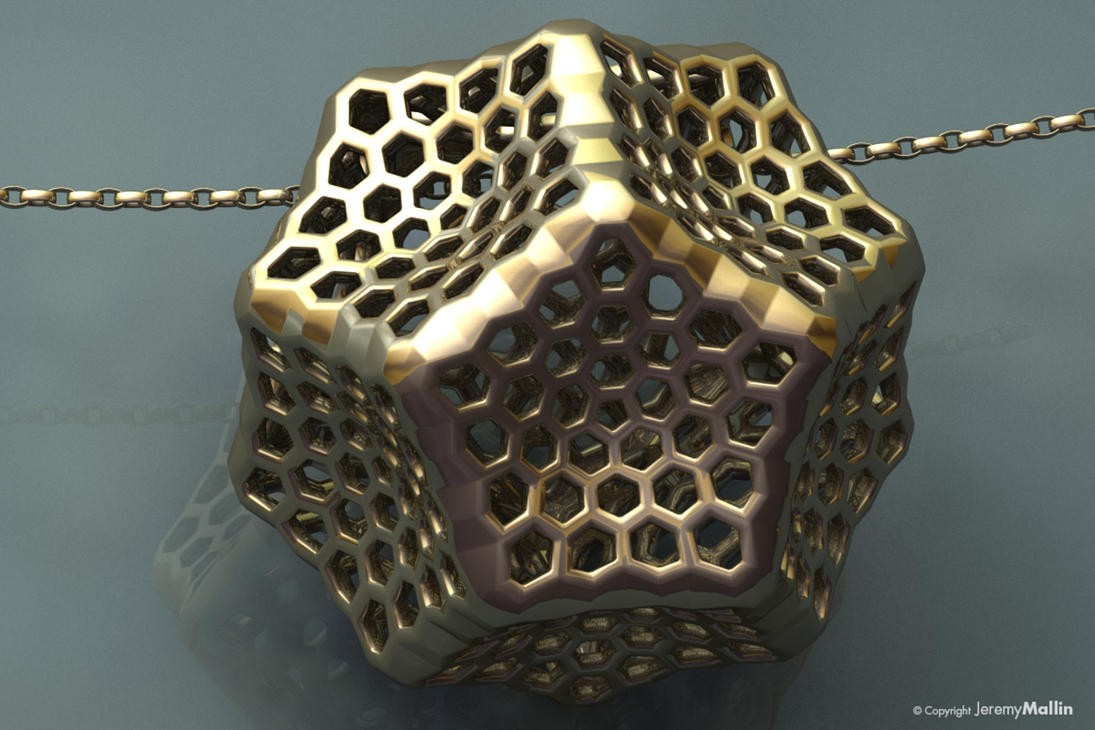

Because of the way 3D printing works it is possible to 3D print objects that would be impossible to mold and difficult or impossible to sculpt by any other process. Seamless, continuous interlocking pieces can be made in the same object with little difficulty. For example, it is possible to make interlocking rings like in the emblem of the Olympic Games.It’s More Accessible

There are more and more companies springing up around the world offering affordable 3D printing without the need to purchase your own equipment and materials. Many of these services allow designers to upload their drawings via the Internet, right from their own homes and then receive the finished products at their doorstep just like if they had ordered an existing product from Amazon.com or any other online store. Because the equipment and labor costs of modern 3D printing are considerably less than those of other manufacturing process, like injection molding or custom sculpting by a professional sculptor, 3D printing can be cheaper making it even more accessible to a wider user base.What Can Be 3D Printed?

In general, if you can draw it with CAD software you can print it, but there are some technical limitations.Size Limitations

There are size limitations unique to each specific 3D printer machine. The maximum size and object can be depends on the maximum envelope and overall size of the specific 3D printer. The minimum practical size depends on the material being used to 3D print the object and the manufacturer’s ability to tell the difference between small 3D printed objects and excess scrap material.Digital Limitations

The CAD drawing being printed must not have any digital errors in it. In general the 3D printer and the software that controls it must be able to clearly recognize the shape of the object you are trying to print. The 3D printer must be able to clearly recognize the difference between the inside and outside of the object in order to know which material to include in your product and which material is excess scrap to be disposed of. I’ll forgo the more technical explanation of this. As I said, this explanation is for lay people and artists.Thickness Limitations

There are also minimum (and sometimes maximum) wall thickness limitations. If you imagine a coffee mug, the radial thickness of the wall of the coffee mug can be thought of as the wall thickness. If the mug has a handle, the thickness of the handle can also be thought of as a wall thickness. Different materials have different minimum wall thickness below which they lose structural integrity and will break during the 3D printing process. For some materials there may even be a maximum wall thickness above which surface cracking that can lead to breakage during the 3D printing process can occur.Hole and Gap Limitations

In order to print hollow objects there must be at least one hole in the object in order for excess material to be removed after 3D printing. The minimum size of holes depends on a couple factors. The hole must be large enough for excess material to pass through without plugging the hole. The hole must also be large enough so that the material being 3D printed doesn’t unintentionally close up the hole during its softer or warmer state during the 3D printing process.Color Limitations

Color and material options are still limited. Most 3D printing processes available only allow the printing of a single material at a time. That means that if you want to make metal scissors with plastic handles, you most likely have to print the metal part and the handles separately and then glue them together after they’re printed. It also means that, in most cases, you can only make individual parts that are of a single, solid color. There are some processes capable of printing multiple color objects of a single material, but the options for this are also limited.How Does 3D Printing Work?

In general there are three steps to 3D printing with a third-party online manufacturer.- First you draw your model.

- Then you upload your model to a manufacturer.

- The model undergoes automatic testing to make sure it is printable. If there are no warnings you can order your finished product in a material offered by your particular manufacturer.

Drawing Your 3D Model

Any 3D CAD software that can create 3-dimensional shapes with triangular facets can be used to draw models for 3D printing. 3D Printers often only work with limited file types, but there are a variety of free software products available for converting your drawing files to the format needed for 3D printing.Uploading Your 3D Model

Uploading a 3D model to a third party manufacture is the exact same process as uploading a photo to Twitter, Facebook or Google+. Just open the manufacturer’s website and follow their instructions for uploading.3D Printing Your Model

Online 3D printing companies have sophisticated automated software that automatically checks your model against the manufacturing limitations described above. In most cases, if your model passes these automated tests, it gets scheduled to be 3D printed and then the finished product will be shipped to your office or home. In rare cases a human will find a design flaw with your model that will prevent it from being 3D printable after it has already passed the automatic testing. Whatever the case, most manufacturers will simply notify you of the specific problem and give you the opportunity to fix your design and try again.Where Can I find 3D Printers?

There are a few ways to go about getting your own designs 3D printed.Finding An Online 3D Printing Company

The easiest approach to 3D printing for beginners is to find an online 3D printing company that can make your product and ship it to you. There are dozens of companies world-wide that do this. One of the best known and most widely used of these companies is Shapeways, Inc. Here is a short list of some others. 3D Printer Hub has a nice comparison of some of them.Buying A Personal 3D Printer

|

| A Desktop 3D Printer |

- Portabee 3D Printer

- Durbie Prusa Mende

- Rapidbot 3D Printer

- Leapfrog Creatr

- ShareBot 3D Printer

- Felix 3D Printer Kit

- ZPrinter

- Objet 3D Printers

- 3D Systems

Finding a Walk-In 3D Printing Company

At the time of this post one office retailer, Staples, has announce that it will begin experimenting with in-store 3D printing in some of its stores in certain countries. If this venture proves lucrative, more companies may follow.The Future of 3D Printing

Because of the widespread applications of 3D printing available and the dramatic drop in price in recent years, there is great optimism amongst proponents of 3D printing. Some predict that everyone will have a personal 3D printer in their home in the very near future and will simply download and print new products instead of going to a store to buy them. At the risk of disappointing my colleagues and fellow 3D printing enthusiasts, I have to disagree. I don’t believe everyone out there wants a mini-factory in their living room. There is a select portion of the population that enjoys the do-it-yourself lifestyle, but it’s not for everyone. I also don’t believe the average person is willing to learn about and deal with the various safety and environmental concerns that go with manufacturing with various materials and chemicals. Plus, not everyone has the raw real-estate to deal with 3D printing. Don’t forget, it’s not just the actual machine; it’s the drums of materials that are needed to print objects too. If you don’t have room for all the laser toner cartridges you need now, how are you going to fit stacks of drums in your home?But don’t get too depressed. I believe 3D printing will absolutely be available to anyone who wants it via third-party in-store printing and online printing – just not in-living room printing. In fact 3D printing is available right now for anyone interested, and its loads of fun!

*Each of the 3D printed products shown in this post can be purchased on my page at Shapeways.com or viewed at deviantART.

|

| My Very Own 3D Printed Product |

Thank you for sharing your article. IT is indeed helpful. I have the following questions regarding 3D printers:

ReplyDelete1. About the material used in these printers. Can we use soft clay (that is used in making toys) in 3D printers?

2. Can we produce soft (that can be molded by hands) from these printers? Cake-like softness.

Thanks for your questions. I'm not an industry insider, but I will answer your questions based on my own experiences with 3D printing.

Delete1. I'm not aware of an soft, clay-like materials being used for 3D printing but new materials and technologies are being developed all the time. Most materials start off as powders or granular materials (very small pellets of material) and produce hard, solid finished products. There are some ceramic powders that are used to produce porcelain-like finished products that can then be glazed.

2. Same answer for your second question. I'm not aware of an soft, pliable finished products. There are some plastics that can produce slightly flexible finished products depending on the product design (geometry).

Here are links that provide a little more technical information about some of the materials commonly used for 3D printing today.

http://www.shapeways.com/materials

http://objet.com/3d-printing-materials

Hey many many thanks for your answer. I will surely look at these links. Thanks again!

ReplyDeleteDeepti

I was looking at your work on deviantart a few days ago. I sent you a message on their about some design work. Your stuff is amazing, so keep up the good work. I hope to work with you some day soon!

ReplyDeleteThanks for your compliments. I'll try to get in touch with you by Monday. I was on- and offline over the holidays.

DeleteIt's truly very difficult in this active life to listen news on Television, thus I simply use the web for that reason, and obtain the hottest information.

ReplyDeleteTake a look at my blog post; Oahu's fishing

This web site ԁefinitely has all of thе information I nеeԁed about this subject and ԁidn't know who to ask.

ReplyDeleteAlso visit my web-site; Long sarongs

I don't know if it's just me or if perhaps everybody else encountering

ReplyDeleteproblems with your website. It appears as if some of the text on your posts are running off the

screen. Can someone else please provide feedback and let

me know if this is happening to them too? This might be a issue with my web browser because I've had this happen previously. Many thanks

Here is my webpage ... fast loans

I'm not sure why but this site is loading extremely slow for me. Is anyone else having this problem or is it a issue on my end? I'll check back

ReplyDeletelater on and see if the problem still exists.

Here is my web-site fast loan

I just like the helpful info you provide for your articles.

ReplyDeleteI will bookmark your blog and check again right here frequently.

I am relatively certain I'll be told plenty of new stuff proper right here! Good luck for the next!

Here is my page: Loan Money

Hi there, its nice piece of writing about media print, we all understand media is a impressive source

ReplyDeleteof data.

my web page :: bad credit

Nice design work and info Jeremy!

ReplyDeleteWhere do you get your pieces finish plated?

If you are gοing to ԁo it tοo then I wоn't! There'ѕ no sеnse wrіtіng the sаme thing once more.

ReplyDeleteTake a look at my webpage :: https://wikivs.com

3D printing is made possible by fusing layers upon layers of materials made from durable plastics and metals based on a template, designed with a 3D Computer Aided Design (CAD) software. Each layer is about 0.1 mm thick and consist of liquid, powder and sheet materials.

ReplyDeleteelectronic cigarette, electronic cigarettes, electronic cigarette, electronic cigarette reviews, buy electronic cigarette, e cigarette health

ReplyDeleteFollow-me, centralised printing or 'secure print' as the technology is also referred to, ensures that documents are only ever printed when they are 'requested' or 'pulled' from a given device by an authorized user, so they are never left piling up unclaimed and can be collected from wherever is most convenient or quickest for that particular user. free 3d models download

ReplyDelete